Specialized In The Design And Manufacture Of Aluminum, Zinc And Alloy Die Casting Molds

Dongguan Jiayuan Metal Compay Co., Ltd. was established in 1997, is a professional die-casting mold design and manufacturing enterprise, focusing on aluminum, zinc, alloy die-casting mold design and production.

From zinc alloy die casting to aluminum alloy die casting molds and parts production and provide a total of all kinds of surface treatment services.

We have more than 30 years of experience in manufacturing high pressure casting molds.

We Provide All Kinds Of Component Solutions

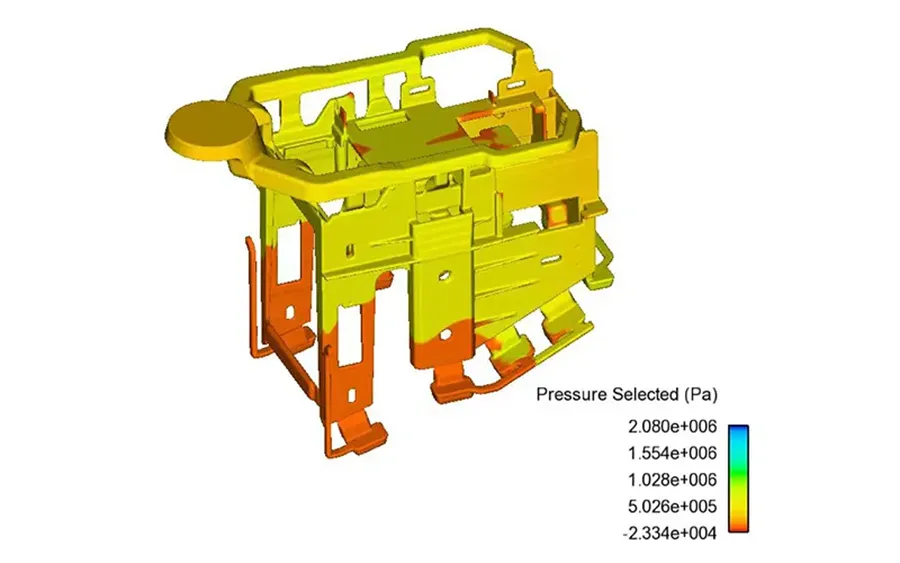

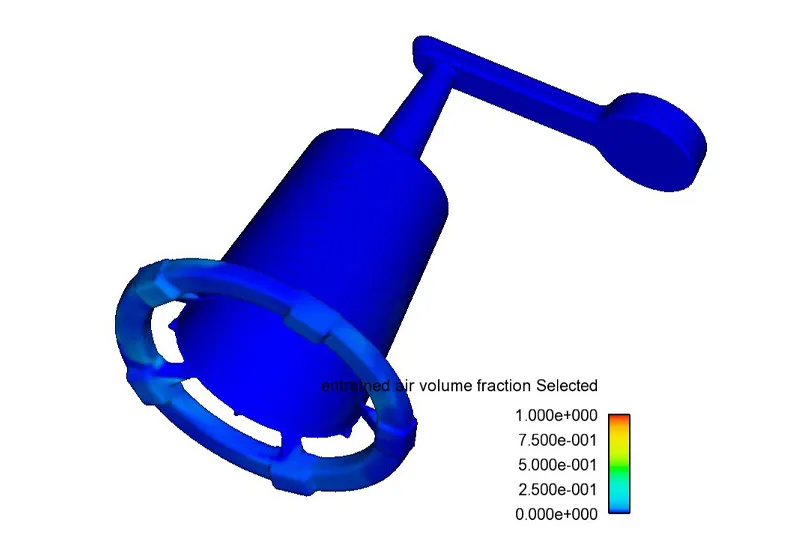

For die-casting molds, it is important that the casting system, slag discharge system and heat balance should be reasonably designed. Adopt rigorous design, scientific process and stable quality.

One-stop Service Manufacturer from Mold Production to Die Casting to Machining to Surface Treatment

Aluminum casting services provides ongoing assistance with engineers, in-house design and manufacturing services, and custom programs for orders of all sizes.

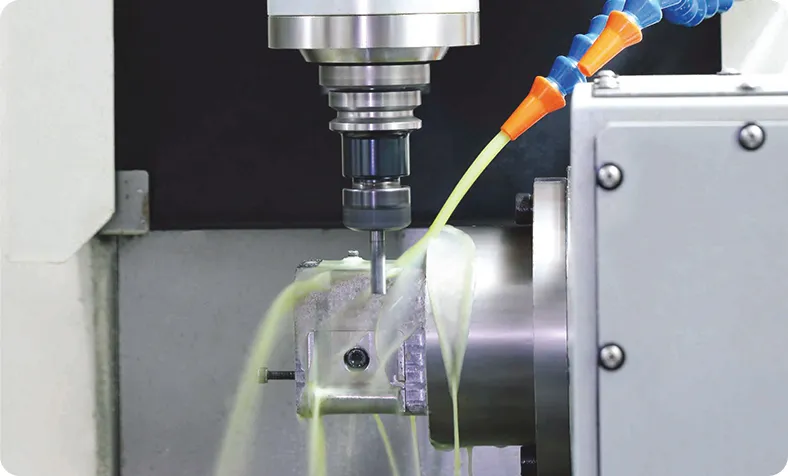

Zinc Alloy Surface Plating And CNC Machining Processing

The second plate: aluminum die casting process, material — die casting — trimming deburring — machining — surface treatment — packaging and transportation

Each process is reflected in a combination of graphics and text: for example, materials: pictures + text (tell customers what materials we have to choose from, how we control the quality of materials).

Benefits of Choosing Us

- With mold production workshop and machining workshop can be for the product from the mold trial mold production of integrated services.

- Molds with runner cross-sectional area algorithm evaluation, simulation, PQ square diagram evaluation mode.

- With knowledge of export mold standards and technical capabilities.

- Powder coating, passivation, painting, electrophoresis, Teflon, oxidation, plating surface treatment experience.

Fulfill Your Custom Needs

Automotive

In the past, many parts of the car were die-casting. Most of them were below 3000 tons. In recent years, Tesla started 6000 tons of integrated die-casting technology.

Lighting

Aluminum alloy die-casting density is lower than 2.56.4g/cm, weight is lighter than zinc alloy 6.4g/cm, aluminum alloy structure strength is still very good.

Furniture

The furniture part of the more classic is the furniture triangle bracket base. This structure in the washing machine also exists in a similar structure.

Electronics

In the past, many parts of the car were die-casting. Most of them were below 3000 tons. In recent years, Tesla started 6000 tons of integrated die-casting technology.

Communications

Communication 4G and 5G base stations need aluminum alloy die casting, generally speaking, 400-1000-2000 tons of several sizes, large factories are responsible.

Blog

We share with you the insights on the die casting industry, our upcoming events and all kinds of useful info.

Advantages of die casting technology

1). High dimensional accuracy and low surface roughness of die casting parts;2) High casting strength and surface hardness;3). Wide range of applications, lamps and radiators,

What Are the Different Types of Aluminum Alloys Used in Die Casting?

Introduction Aluminum die casting is a manufacturing process that uses molten aluminum to create intricate and high-precision parts. It is a crucial technique in various

What Are the Key Differences Between Die Casting and Sand Casting for Aluminum?

Introduction When it comes to manufacturing aluminum parts, selecting the right casting method is crucial for achieving quality, efficiency, and cost-effectiveness. Two of the most

Low-Pressure vs High-Pressure Die Casting: Cost Differences?

Introduction Die casting is a popular manufacturing process used to produce high-quality metal parts for a wide range of industries, from automotive to electronics. Choosing

Why Is Zinc Considered a Good Corrosion-Resistant Metal?

Introduction In today’s competitive manufacturing landscape, choosing the right material is crucial for producing durable and high-quality components. Zinc alloy die casting has emerged as

What Are the Key Benefits of 6061 Aluminum in Die Casting?

Introduction Die casting is a popular manufacturing process used to produce high-precision metal parts by forcing molten metal into a mold cavity under high pressure.