Quality

Quality Policy

Everyone Participates

All departments and products within the company organization are given rights and responsibilities related to quality control, and appropriate resources are provided so that all personnel can fully participate in quality activities.

Keep Improving

Continuously improve the quality of enterprises and institutions, create competitive advantages, and make continuous progress.

Precision And Refinement

There is no best, only better, pursue perfection in product quality, efficiency, cost and delivery time, and provide customers with better products and services.

Customer Satisfaction

Fully cooperate with customers, effectively utilize resources, and meet customer requirements to the greatest extent possible.

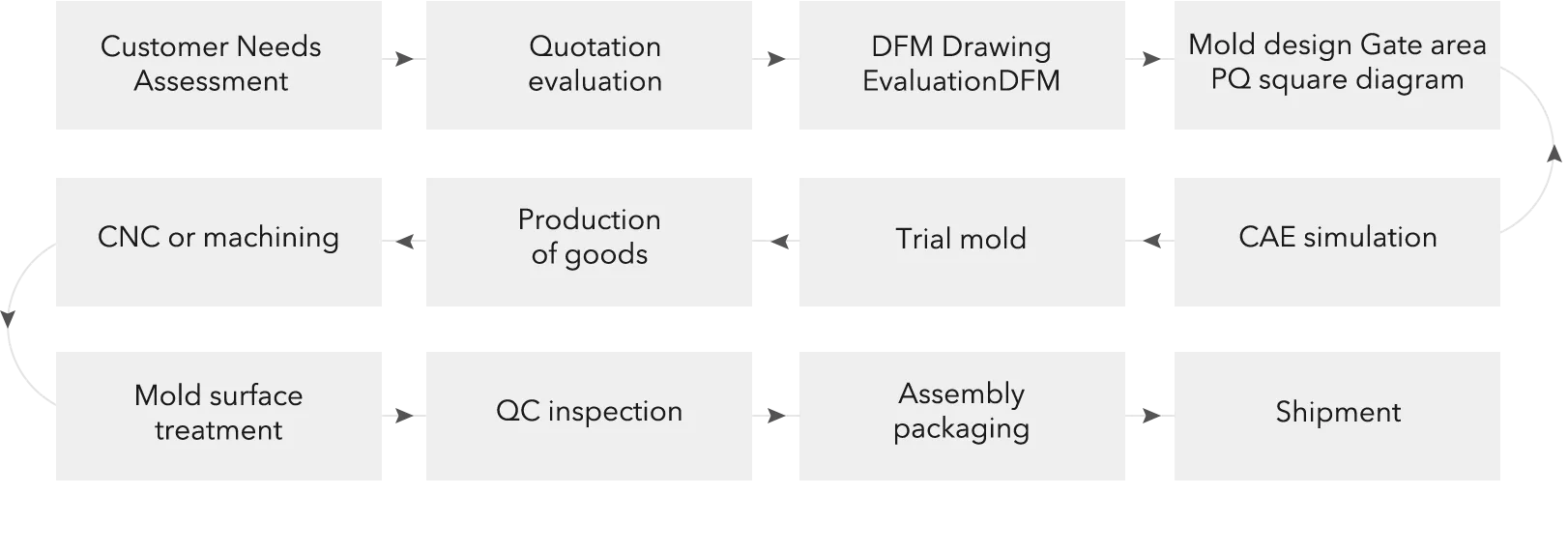

Order Process Follow Up

Quality Department Test Machine

Three-dimensional detection

Xray fluorescence analyzer

Xray inspection

Oxford instruments direct reading spectrometer

Strength testing machine

Salt spray test

Die Casting Gate Area Calculation

Importance of Gate Area Calculation in Die Casting

Die casting is a manufacturing process that involves the production of complex shapes and components by injecting molten metal into a mold cavity under high pressure. The process requires proper design and calculation of the gate area to ensure the production of quality and accurate parts. This blog will provide a detailed guide on die casting gate area calculation, including its importance, factors that influence the gate design, and the steps involved in the calculation.

The gate is an essential component in the die casting process, as it serves as the channel through which the molten metal flows into the mold cavity. The gate design and size significantly influence the quality of the parts produced. It is, therefore, crucial to calculate the gate area accurately to prevent defects such as porosity, gas entrapment, shrinkage, and flash. Proper gate sizing also helps to optimize the casting process, reduce cycle time, and minimize production costs.

Factors Influencing Gate Area Design

Several factors influence the gate design, and they include

Part Geometry

The shape and size of the part to be cast determine the gate location and size.

Material Type

The type of material used affects the fluidity and viscosity of the molten metal, which affects the gate size.

Wall Thickness

The thickness of the part wall determines the gating system to use and the location and size of the gate.

Casting Machine Pressure

The pressure required to inject the molten metal into the mold cavity influences the gate design.

Surface finish

The desired surface finish affects the gate location and size.

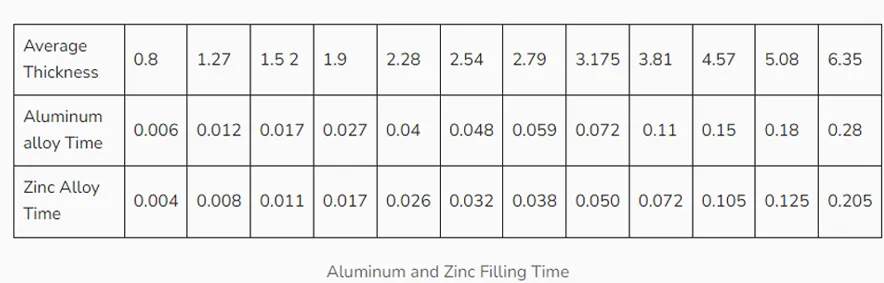

The formula for calculating the internal gate cross-sectional area

Ag = G / pVg t

Ag = cross-sectional area of the internal gate

G = mass of metal liquid passing through the inner gate

p = liquid aluminum density of 2.4g/cm3

Vg = flow rate of metal liquid through the inner gate

T = filling time

Certificates