Automotive

Get high-quality manufacturing services for your custom automotive prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

One-stop Service Manufacturer from Mold Production to Die Casting to Machining to Surface Treatment

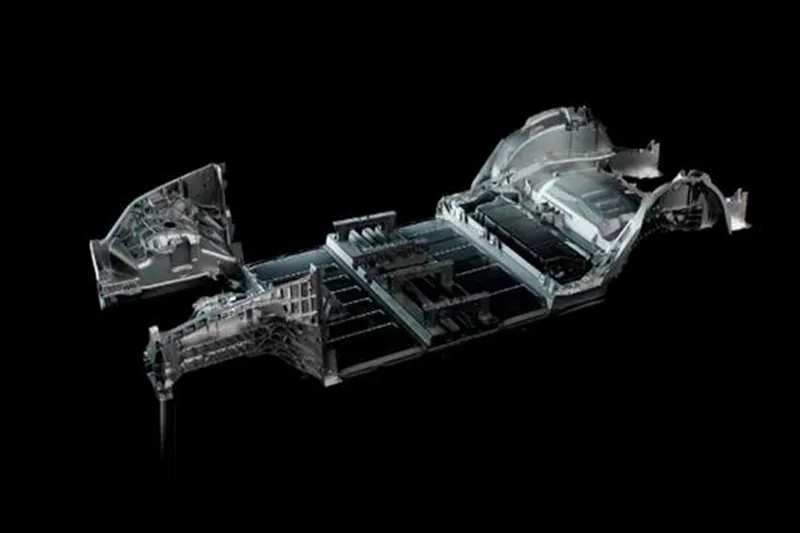

In the past, many parts of the car are die-casting, most of them are below 3000 tons, in recent years, Tesla started 6000 tons of integrated die-casting technology to drive the whole industry towards integrated die-casting technology, and at present, we are seeing 9000 tons and 12000 tons of die-casting machine, which can make 70 stamping parts into 1, and the heat conductivity is better after the battery is overheated, and the manufacturing area can be reduced by 40%. Basically, new energy vehicle manufacturers are vigorously developing towards this.

- Experienced Engineers

- Advanced Machines

- Scientific Management

- Craftsmanship Spirit

Tesla integrated die-casting, and ultimately may reach 20,000 tons to 30,000 tons forward, their ultimate goal is estimated to be the welding points of the parts gradually replaced by die-casting, Ford in 1913 or so to reduce the cost of automobiles using the assembly line, Toyota 1937 put forward the Just in time lean production after two generations of hard work, Toyota cars have been sold worldwide after 1980, the advantages of lean production! Lean production advantages can mainly control the time control materials hybrid car production models, to 1980 after the computerized miniaturization, a large number of production line machines and clerical management system using computerized processes, a large number of first-class car factories, whether from simulation production need to be simulated through the computer to establish the production line, to ensure that the construction of the production line after the construction of a new problem.

Why Choose JIAYUAN?

ISO certified

JIAYUAN is an ISO9001-2015 certified manufacturer that can guarantee top quality parts in an industry that demands rigorous consistency and quality control.

Huge production capacity

We can fulfill orders of virtually any size.

Range of services

As an equivalent parts shop and digital manufacturing expert, we provide CNC machining and manufacturing technology and services.

Easy quotation system

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Skilled and experienced

We have been manufacturing automotive parts for over a decade and our skilled engineers know how to get the best outcomes from your designs.

Short lead time

Our extensive facilities and partner network allows us to fulfill orders quickly, no matter the quantity or complexity.

What kind of automotive parts can we make?

Currently, Tesla is building the fourth automotive manufacturing revolution in the automotive industry at its Mexico mega-factory, and there are two main differences in this revolution. The first one is to increase the self-manufacturing rate, and the second one is to change the open-box process.

- The first point is to increase the self-manufacturing rate.

- The second point of Tesla's unboxing process

The disadvantage of this process is that once the production line is completed, the car type cannot be changed easily. Tesla knows which cars are more popular from the data of Toyota, Volkswagen and other large companies in the past, and these data have been accumulated for nearly 100 years. In fact, Tesla will only use this data to make 10 cars according to the starting space, and only 4 cars may account for 90% of the sales volume. In 2024, more die-casting machines will go to Mexico, and once the die-casting process is successful, Tesla’s new robot taxi will enter the market with the Autopilot FSD system.

The key to electric vehicles is batteries, die-casting, software, in fact, fuel cars can run about 300,000 kilometers, but Tesla-class electric cars have been proven to run 1 million kilometers, in fact, the logistics of long-term replacement of electric cars, electric cars have not actually solved the problem of spontaneous combustion, not charging or range seems to have been solved, fuel cars can only be consumed by the U.S., Europe, China, Japan and the rest of the world is very difficult to consume fuel cars. The rest of the world has a hard time consuming fuel cars.

Automotive Part Gallery

Die casting 6000 tons of a set of molds 24 million a set of mansion costs, a machine needs three sets of molds a model needs six die-casting machines, 18 sets of molds need to be changed every year 4-5 billion just the cost of molds, integrated die casting once Toyota Volkswagen and so on, all use this very large market, the past large factories concerned about 1,000-3,000 tons of die casting, die casting in the next 10-30 years up to 20,000-30,000 tons of die casting machine, a large number of die casting to replace.

FAQ

First of all, customers need to send 3d, 2d drawings need to specify the material and precision requirements of our engineers can be carried out on the product molds and processing costs of the quotation. quotation usually takes 1 day because the main engineering and the boss on this side to review the quotation. Once the quote is confirmed, we can enter the engineering communication.

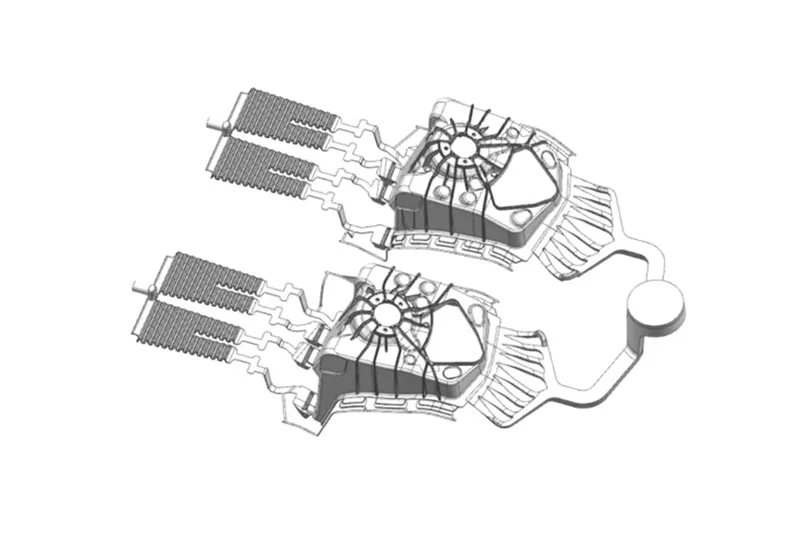

We provide a detailed DFM to ensure that subsequent problems can be minimized, firstly for thickness and chamfering corrections, then for mold pulling or structure that is not conducive to flow resulting in sand holes, skinning, cold segregation, as well as communication on the accuracy of the mounting position.

After confirming the DFM, we will start the molding process.

1:Drilling and tapping by milling machine or deep hole drilling.

2: CNC roughing

3: Hardening 46-48° (hardness depends on the size)

4: Fine milling to hit the right angle

5: CNC finishing

6: EDM discharge

7: CMM three-dimensional measurement (no three-dimensional can height ruler check)

8: Mold saving

9.Assembly

Temperature of the furnace → lifting the mold into the mold → locking the mold slot → locking the screw holes of the tie rods → connecting the oil pipe to the slider cylinder → adjusting the base action without error or interference → connecting the oil and water circuits → the temperature of the mold is determined → checking the PQ square diagram to adjust the pressure and punch speed

→Trial mold 100PCS→No obvious defects on the surface of the mold.

Scrape the cape burr→CNC processing→drilling and tapping→polishing and grinding→powder spraying surface treatment→sending samples to customers to confirm the samples→signing sample card→both sides confirm the sample board→conducting trial production→shipping to customers.