Electronics

Get high-quality manufacturing services for your custom electronics prototypes and production parts. Launch products faster, reduce risks, and streamline production processes with on-demand production at competitive prices.

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

Focus on electronic products and production parts manufacturers

In fact, there are many die-casting in the electronic industry, such as headphones, stereos, cell phone center panels, and notebooks.

Usually notebook or cell phone center plate need to use a lot of CNC to keep the casting precision, size tolerance, most of the cell phone and notebook are magnesium alloy die casting, in the past NOKIA use magnesium alloy die casting less, resulting in a cell phone once the fall of the two lids may also be disintegrated, magnesium alloy die casting through the center plate to greatly enhance the cell phone grip and strength, basically cell phone fall can also guarantee the strength of the reason.

Why Choose JIAYUAN?

ISO certified

JIAYUAN is an ISO9001-2015 certified manufacturer that can guarantee top quality parts in an industry that demands rigorous consistency and quality control.

Huge production capacity

We can fulfill orders of virtually any size.

Range of services

As an equivalent parts shop and digital manufacturing expert, we provide CNC machining and manufacturing technology and services.

Easy quotation system

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Skilled and experienced

We have been manufacturing automotive parts for over a decade and our skilled engineers know how to get the best outcomes from your designs.

Short lead time

Our extensive facilities and partner network allows us to fulfill orders quickly, no matter the quantity or complexity.

What kind of Electronics parts can we make?

The main reason why cell phone needs to use magnesium alloy die-casting is that magnesium alloy density is 1.8g/cm, which is basically close to plastic and can provide strength, magnesium alloy die-casting is very worried that it will explode in rainy days or too much dust will be accumulated, at present, magnesium alloy die-casting factories will carry out dehumidification modification for air-conditioning system, coupled with the advancement of material science, many manufacturers are now adopting a new generation of liquid metal, similar to aluminum alloy, but it can provide lightness and strength similar to magnesium alloy. It is lightweight and strong and reduces the danger of magnesium alloy.

Headphones and stereos are also a lot of die-casting parts, zinc alloy and aluminum alloy have aluminum alloy more than the surface treatment requirements are very high, the surface of the blistering, skinning, water lines on the surface of the headset manufacturers can not be accepted, in fact, the requirements are very high, in recent years, electronic cigarettes are also part of the zinc alloy die casting and aluminum alloy die casting and aluminum processing with the profiles in the shape limitations are quite high, and part of the Xiangshang some manufacturers to try to die casting! The use of 6063 pure aluminum die casting, or DM32 die casting oxidized material, the above also have their own problems, so at present, this thing according to the situation to do with.

- Tight tolerances for critical parts and assemblies

- Wear-resistant materials with certifications

- Excellent quality control via on-machine inspection and/or CMM

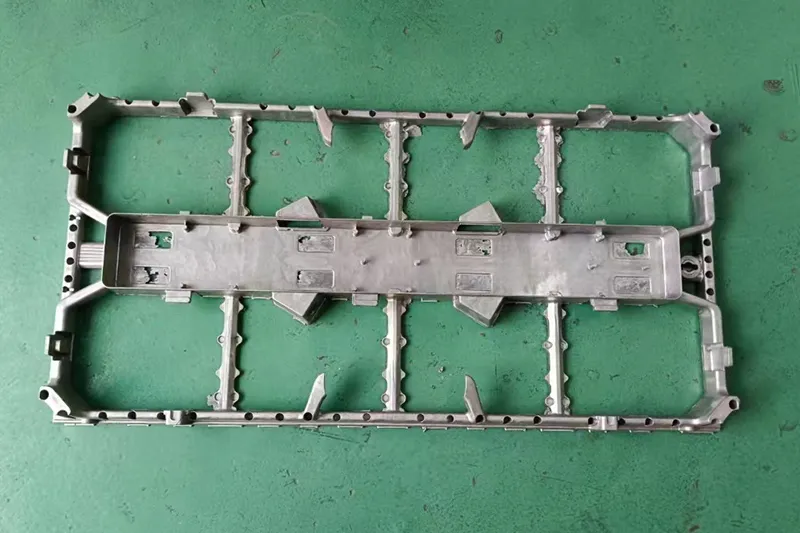

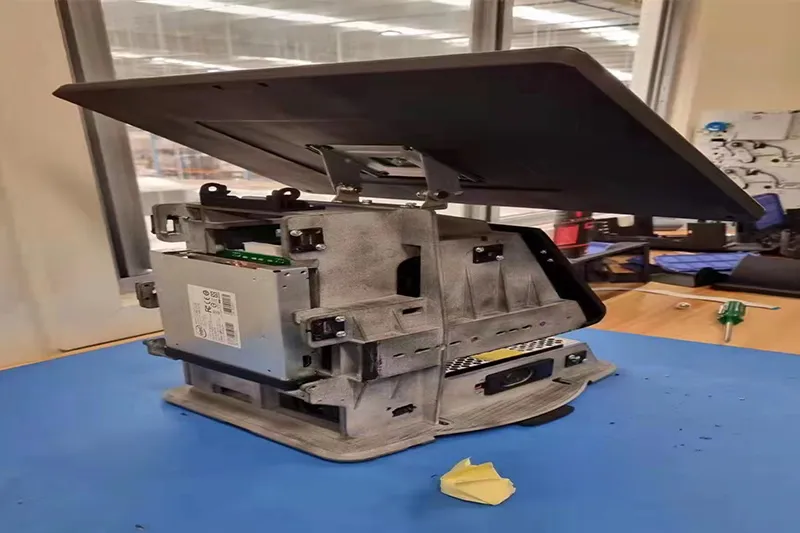

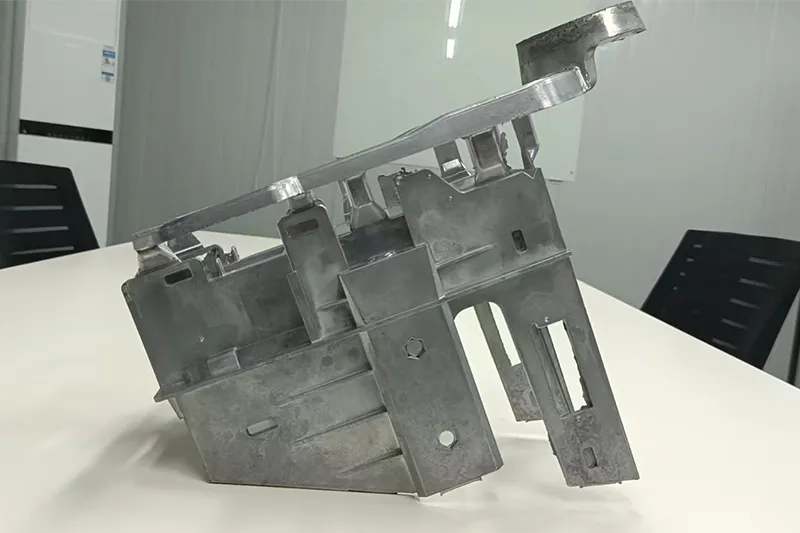

Electronics Part Gallery

Below are some of the types of Electronics parts we can manufacture for you:

- Sweeping robot parts

- Washing machine parts

- Smartphone parts

- Smart speaker parts

- Remote control device parts

- Projector parts

- Digital camera parts

- TV series parts

- Bluetooth headset parts

- Desktop computer parts

- Digital camera parts

FAQ

First of all, customers need to send 3d, 2d drawings need to specify the material and precision requirements of our engineers can be carried out on the product molds and processing costs of the quotation. quotation usually takes 1 day because the main engineering and the boss on this side to review the quotation. Once the quote is confirmed, we can enter the engineering communication.

We provide a detailed DFM to ensure that subsequent problems can be minimized, firstly for thickness and chamfering corrections, then for mold pulling or structure that is not conducive to flow resulting in sand holes, skinning, cold segregation, as well as communication on the accuracy of the mounting position.

After confirming the DFM, we will start the molding process.

1:Drilling and tapping by milling machine or deep hole drilling.

2: CNC roughing

3: Hardening 46-48° (hardness depends on the size)

4: Fine milling to hit the right angle

5: CNC finishing

6: EDM discharge

7: CMM three-dimensional measurement (no three-dimensional can height ruler check)

8: Mold saving

9.Assembly

Temperature of the furnace → lifting the mold into the mold → locking the mold slot → locking the screw holes of the tie rods → connecting the oil pipe to the slider cylinder → adjusting the base action without error or interference → connecting the oil and water circuits → the temperature of the mold is determined → checking the PQ square diagram to adjust the pressure and punch speed

→Trial mold 100PCS→No obvious defects on the surface of the mold.

Scrape the cape burr→CNC processing→drilling and tapping→polishing and grinding→powder spraying surface treatment→sending samples to customers to confirm the samples→signing sample card→both sides confirm the sample board→conducting trial production→shipping to customers.